Porotech optimizes bonding process, actively implements MicroLED mass production

Porotech optimizes bonding process, actively implements MicroLED mass production

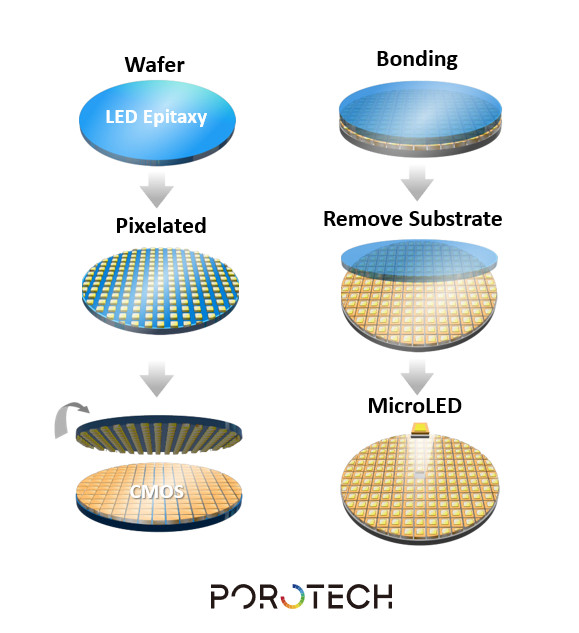

"Porotech, a pioneer in the microLED field, is honoured to have been invited to participate in the ""Metaverse X Technological Evolution X Application Innovation"" Forum. Porotech shared their game-changing technology - DPT® (Dynamic Pixel Tuning®) in the forum, and how to use wafer to wafer bonding technology to achieve the commercialization goal of high-yield, low-cost, full-colour microLED mass production, truly bringing microLED into everyone's life. "

Micro LED has been hailed as the new star of the next display generation due to its excellent performance. However, the supply chain has yet to enter a mature stage for microdisplays due to the boundaries of related process technologies, failing to enter large-scale commercial applications.

"In 2020, Porotech developed a unique material, PoroGaN®, which enabled the world's first InGaN red light display, facilitating the use of InGaN materials for all three colours of R/G/B displays without unnecessary losses in the manufacturing process, which is a revolutionary first step for process simplification. In 2022, we replaced the traditional spatial light mixing method with field sequential colour mixing in the original technology. We later announced our proprietary DPT® (Dynamic Pixel Tuning®) technology, where only a single LED can produce monolithic full-colour displays. With these rapid adjustments, MicroLED production has become more efficient, thinner and lighter displays, all while while maintaining excellent image quality.

We look forward to having in-depth discussions with industry colleagues at this LEDinside forum to shape microLED's future jointly."