Improve the accuracy of LED light flux measurement in integrating sphere

According to the particularity of LED luminous flux measurement, the design of the integrating sphere for LED measurement adopts a unique optimization, combined with high reflectivity diffuse material, which greatly improves the stability and accuracy of the system. Experimental results show that the stability and consistency of the system are much higher than other common LED testing systems. It is really suitable for LED optical parameters measurement system.

Brief introduction:

Different from traditional light sources, the accuracy of LED light flux measurement is challenged in the process of using integrating sphere to measure light flux. On the one hand, leds are generally more directional than traditional light sources and do not glow evenly throughout the space. This feature makes the LED direct light distribution uneven on the surface of the integrating sphere. This uneven distribution will cause the direct light of different leds to have different reflection characteristics of the detector. Since the position of the detector and the position of the baffle are fixed, the direct performance of the various reflection distributions is signal fluctuation. In the common test system, there are differences in LED with different luminous angles, and the same LED has the same emission in different positions with different placement directions. Even if the rated luminous flux is the same; The actual measurements are different. According to the customer's verification results, the influence of the placement direction of the LED in the common LED test system on the luminous flux measurement results is always more than 50%(the difference between the maximum and minimum signals of the same LED measured in different directions).

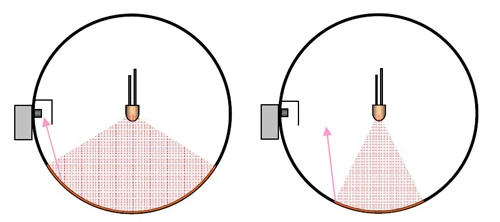

When measuring different LED luminescence angles, the distribution of direct reflection has different influences on detectors due to the difference in the distribution of the internal surface of the integrating sphere, which directly affects the difference in measurement accuracy (as shown in the figure).

On the other hand, LED test systems usually use halogen tungsten lamps as the standard light source. Compared with LED, the standard lamps used have great differences in appearance, lighting distribution characteristics and spectral characteristics. Therefore, the difference between the two should be corrected by absorption coefficient.

Analysis:

The reflection characteristic inside the integrating sphere is one of the key factors that make LED directivity affect the measurement accuracy. In common LED testing systems, the reflectivity and Lambert characteristics of the integrating sphere surface coating are not ideal. One reason is low reflectivity, the other is poor diffuse reflectance. The result of the low reflectivity of the integrating sphere surface is that the direct light of the LED gradually decays after several reflections. However, in the whole light mixing process, both direct and reflected light occupy a large proportion, which is dominant. In some cases, low reflectivity materials can create a strong shadow effect on the backside of the baffle probe. However, it is the straight-line reflection of light and shadow that leads to inaccurate measurements.

In addition, low diffuse reflectance will seriously affect signal attenuation. In the process of light measurement, the light is reflected several times in the integrating sphere, and each reflection will produce certain attenuation, but the influence of the reflectance on the light intensity is strengthened after several reflections. For example, if the reflected light is reflected 15 times in the integrating sphere, the signal attenuation may be more than doubled if there is a 5% difference between reflectance. In fact, the reflectivity of the integrating sphere varies much more than this.

Current LED testing systems do not have standard leds that are used as standard light sources. In the measurement process, we still choose to use the standard halogen tungsten lamp as the standard light source. Due to the large difference in the external structure of the standard lamp and the measurement LED, including the light absorption effect of the LED holder and the difference between the standard lamp installation position and the LED installation position, all of these are important factors affecting the accuracy of the test results.

Solution:

Lpce-2 spectrometer & Integrating Sphere LED test system is a set of LED test system developed by Shanghai Lishan Electronics, which fully meets the requirements of LM-79 and CIE, and effectively solves various defects of traditional LED test system. Compared with the mass assembly technology of traditional integrating sphere, the integrated sphere is produced by the one-time molding technology of Lyshan Electronics, and its shape completely conforms to the spherical structure of 4π or 2π. The lishan electronic integrating sphere also uses high reflection and diffuse rate coatings so that the lamp is designed to be in an open position aligned with the detector position. This improvement resulted in good consistency of test results, even when using highly directional leds or using position mode under extreme conditions.

The LPCE-2 uses a standard halogen tungsten lamp as a standard lamp combined with an optional auxiliary lamp to measure the effect of the difference between the LED and standard lamp holder on the test results. This standard lamp has been strictly calibrated by Lishan Electronic calibration laboratory; The test results were traceable to NIM.

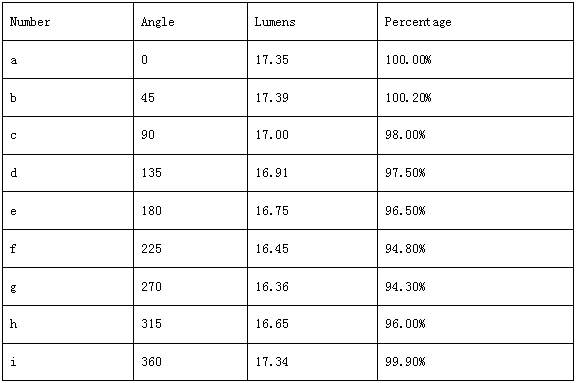

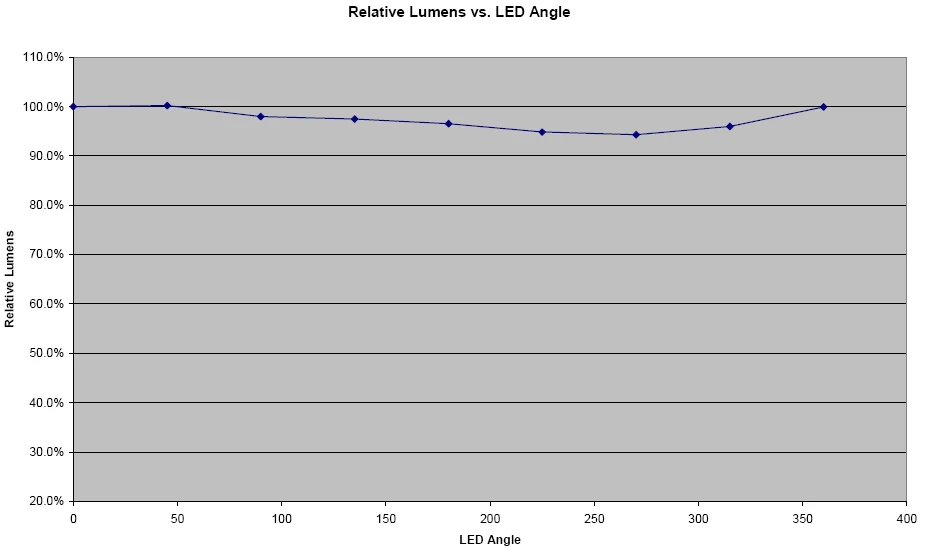

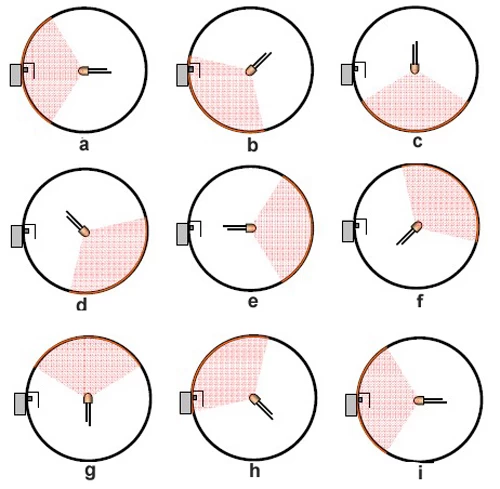

In view of the accuracy of the above LED test results, lPCE-2 test system was used to carry out the corresponding test. The test conditions are as follows: use 5 high brightness green leds with power of approximately 0.35W and lighting Angle of approximately 30°. The LPCE-2 test system is used for nine measurement positions representing possible LED position patterns, as shown in the figure.

Conclusion:

The relationship between measured light flux and LED position mode is shown in FIG. 4 and 5. It can be seen from the test results that even in the most extreme case, when the LED is placed in front and behind the detector's opening, the peak of the luminous flux test result is still less than 5%. This is a very good test result. In the actual testing process, the repetition error of LED luminous flux measurement was much less than 0.1%. It can be seen that the test results of THE LPCE-2 test system are reliable and stable, which can provide a reliable guarantee. This standard system not only supports THE DEVELOPMENT and production of LED, but also is the ideal choice for optical performance measurement in the LED industry.